Understanding Oil Coolers: A Comprehensive Guide

Oil coolers are essential components in various types of machinery, especially in automotive applications. But why do they matter? Imagine trying to cook a meal on a stove that’s overheating. The heat can ruin the dish, and similarly, excessive heat can damage your engine or equipment. This is where oil coolers step in, helping regulate temperatures and ensuring optimal performance. Let’s dive deeper into the world of oil coolers, explore their importance, and understand how they work.

What is an Oil Cooler?

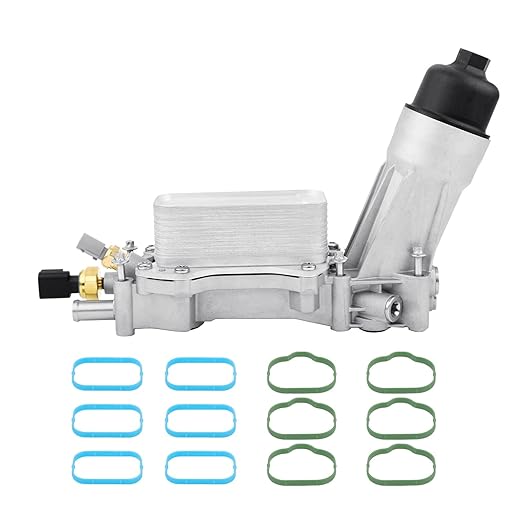

An oil cooler is a type of heat exchanger specifically designed to reduce the temperature of engine oil or hydraulic fluid. By maintaining lower oil temperatures, these coolers help improve the efficiency and longevity of the engine. Think of it as a cooling system for your vehicle’s lifeblood—its oil. When oil is kept at a consistent and optimal temperature, it can perform its job of lubricating and protecting engine components effectively.

How Do Oil Coolers Work?

Oil coolers operate on the principle of heat exchange. They typically consist of a series of tubes or plates through which the oil flows. As the oil travels through these channels, it releases heat to the surrounding air or coolant, which is often facilitated by the vehicle’s radiator system. This process is akin to how a radiator cools water in your car. The cooler the oil, the better it can perform its protective duties.

Types of Oil Coolers

There are primarily two types of oil coolers: air-cooled and liquid-cooled.

Air-Cooled Oil Coolers

Air-cooled oil coolers use ambient air to dissipate heat. Imagine standing in front of a fan on a hot day; the air flowing past you cools you down. Similarly, air-cooled oil coolers have fins that increase surface area, allowing more air to contact the cooler and enhance heat dissipation. They are often used in smaller engines or racing applications where weight is a crucial factor.

Liquid-Cooled Oil Coolers

Liquid-cooled oil coolers incorporate the vehicle’s coolant system to help regulate oil temperature. This method is more efficient than air cooling, particularly for larger engines that generate significant heat. Picture a river flowing through a valley—the water absorbs heat from the rocks and cools down before continuing its journey. Liquid-cooled oil coolers work on a similar principle, using coolant to remove heat from the oil.

The Importance of Oil Coolers

Now, you might wonder, why should I care about oil coolers? The truth is, neglecting oil temperature can lead to several issues, including:

1. **Engine Overheating**: Just like an overheated stove can burn your food, an overheated engine can lead to catastrophic failures. An oil cooler helps maintain temperatures, preventing overheating.

2. **Improved Lubrication**: Oil that’s too hot loses its viscosity, reducing its ability to lubricate engine parts. This can result in increased wear and tear, leading to costly repairs.

3. **Enhanced Performance**: Cooler oil means better performance. Just as athletes perform better when well-hydrated, engines run more efficiently when their oil is at the right temperature.

Choosing the Right Oil Cooler

When selecting an oil cooler, consider factors such as:

– **Compatibility**: Ensure the oil cooler is compatible with your vehicle’s make and model.

– **Type of Use**: Determine whether you need an air-cooled or liquid-cooled system based on your driving conditions and engine size.

– **Size and Design**: The size of the oil cooler should match your engine’s needs. A larger cooler may be necessary for high-performance or heavily loaded vehicles.

Installation and Maintenance

Installing an oil cooler may seem daunting, but with the right tools and knowledge, it’s manageable. Most oil coolers come with installation kits, including hoses and mounting brackets. However, if you’re unsure, it’s always wise to consult a professional mechanic.

Once installed, regular maintenance is key. Inspect hoses for leaks and ensure the cooler is free of debris to maintain airflow. Think of it as checking the air filter in your home; neglecting it can lead to poor performance.

Conclusion

In summary, oil coolers play a critical role in maintaining the health and performance of your engine. By managing oil temperatures, they prevent overheating, enhance lubrication, and improve overall efficiency. Whether you’re a casual driver or a performance enthusiast, understanding the importance of oil coolers can save you time and money in the long run.

FAQs

1. How often should I check my oil cooler?

It’s a good practice to inspect your oil cooler during regular oil changes or every 5,000 to 7,500 miles. Look for any signs of wear or leaks.

2. Can I install an oil cooler myself?

Yes, if you have basic mechanical skills and the right tools, you can install an oil cooler. However, if you’re unsure, it’s best to consult a professional.

3. What are the signs of a failing oil cooler?

Common signs include overheating engines, oil leaks, and a decrease in engine performance. If you notice any of these symptoms, it’s essential to get your cooler checked immediately.