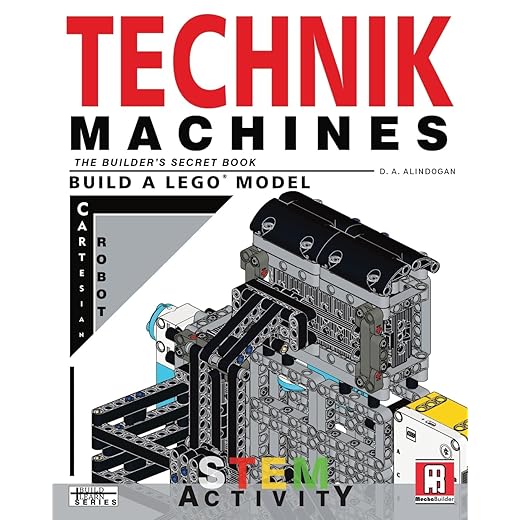

Understanding Cartesian Robots: The Precision of Motion

In the ever-evolving world of automation, Cartesian robots stand out as a beacon of simplicity and efficiency. These robots, often referred to as linear robots, utilize a straightforward mechanism that translates movement along three axes: X, Y, and Z. Imagine a robotic arm that can move just like a printer head, gliding smoothly across a sheet of paper. This basic yet powerful concept underpins the functionality of Cartesian robots, making them indispensable in various industries.

What is a Cartesian Robot?

At its core, a Cartesian robot is defined by its ability to navigate a three-dimensional space through linear movements. Unlike their more complex counterparts, such as SCARA or articulated robots, Cartesian robots utilize a series of motors and linear actuators to achieve precise positioning. Think of it like a high-tech version of a crane, lifting and placing objects with incredible accuracy based on a predetermined coordinate system.

The Anatomy of a Cartesian Robot

To appreciate the brilliance of Cartesian robots, it’s essential to delve into their components. A typical Cartesian robot consists of:

1. **Base**: This provides stability and supports the entire structure.

2. **Rails**: These linear guides allow for smooth horizontal and vertical movements.

3. **Actuators**: Usually in the form of stepper motors, these power the movements along the X, Y, and Z axes.

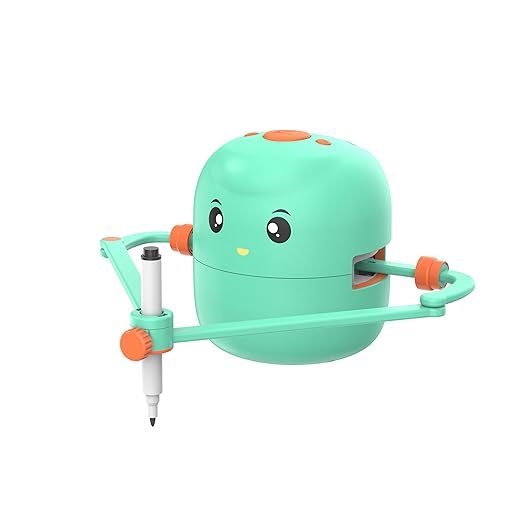

4. **End Effector**: The ‘hand’ of the robot, which can be customized to perform various tasks, from picking and placing to welding and painting.

Consider the end effector as the robot’s tool—similar to how a painter selects a brush for a masterpiece. The choice of end effector can significantly influence the robot’s application, making it versatile across numerous fields.

Applications of Cartesian Robots

The versatility of Cartesian robots is astounding. They find applications in:

– **Manufacturing**: From assembly lines to packaging, Cartesian robots streamline production processes, enhancing efficiency and reducing human error.

– **Medical Field**: These robots assist in surgeries, providing precise movements that can be crucial in delicate procedures.

– **3D Printing**: The mechanics of Cartesian robots are the backbone of most 3D printers, allowing for intricate designs to come to life layer by layer.

– **Material Handling**: Whether it’s moving heavy parts in a warehouse or sorting items, Cartesian robots excel in logistics.

Imagine a factory where every component is assembled with pinpoint accuracy, or a surgical procedure where the slightest tremor could lead to complications. In such scenarios, Cartesian robots not only enhance productivity but also improve safety and precision.

Advantages of Cartesian Robots

Why should you consider a Cartesian robot for your automation needs? Here are several compelling reasons:

– **Simplicity**: Their straightforward design makes them easy to program and maintain. You don’t need to be a robotics expert to operate one.

– **Cost-Effectiveness**: Often, they are less expensive than other robotic systems, making them an attractive option for businesses looking to automate on a budget.

– **Precision**: With their ability to perform repetitive tasks with high accuracy, Cartesian robots minimize errors, ensuring consistent quality in production.

– **Flexibility**: They can be easily adapted with various end effectors, allowing for a wide range of applications without the need for entirely new systems.

Consider the analogy of a Swiss Army knife. Just as it has multiple tools for different tasks, a Cartesian robot can be equipped for various applications, making it a highly adaptable solution.

Challenges and Limitations

While Cartesian robots are powerful tools, they are not without their challenges. For instance, their linear design limits movement to specific axes, which may not be suitable for every application. Additionally, in environments that require more complex movements, other robotic systems may outperform them. It’s essential to evaluate your specific needs before investing in a Cartesian robot.

Conclusion

In summary, Cartesian robots offer a unique blend of simplicity, precision, and versatility that can revolutionize various industries. They are a testament to how straightforward engineering can yield powerful solutions. As you consider the future of automation, think of Cartesian robots not just as machines, but as indispensable partners in your quest for efficiency and excellence.

FAQs

1. How do Cartesian robots differ from other robotic systems?

Cartesian robots primarily move along straight lines in three dimensions, while other robotic systems may have more complex jointed movements, allowing for greater flexibility.

2. What industries commonly use Cartesian robots?

They are widely used in manufacturing, healthcare, logistics, and 3D printing due to their precision and reliability.

3. Can Cartesian robots be programmed for different tasks?

Absolutely! One of their key advantages is the ability to change end effectors, allowing them to perform a variety of tasks with minimal reconfiguration.