Understanding Assembly Conveyors: A Comprehensive Guide

Assembly conveyors are an essential part of modern manufacturing and assembly lines. They streamline processes, enhance productivity, and ultimately contribute to a company’s bottom line. But what exactly are assembly conveyors, and how do they work? Let’s dive into the details.

What is an Assembly Conveyor?

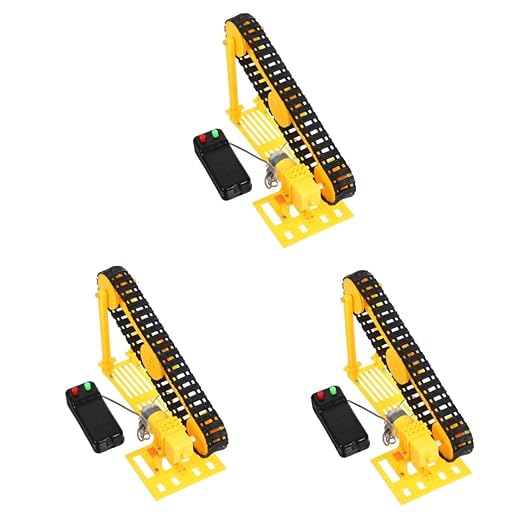

At its core, an assembly conveyor is a mechanical system designed to transport materials or products from one location to another within a production facility. Think of it as a moving sidewalk for your products, facilitating the flow of items through various stages of assembly. These conveyors come in various types, including belt conveyors, roller conveyors, and chain conveyors, each serving unique purposes.

How Do Assembly Conveyors Work?

Imagine a well-orchestrated symphony where every musician plays their part in harmony. Similarly, assembly conveyors operate through a series of interconnected components working together to ensure smooth material flow. The system typically consists of a moving belt or platform that carries products, sensors that monitor movement, and controls that manage speed and direction.

The beauty of assembly conveyors lies in their adaptability. They can be configured to accommodate products of different shapes and sizes, making them versatile tools in any manufacturing setting. Whether you’re assembling small electronic components or heavy machinery, there’s likely a conveyor system tailored to your needs.

The Benefits of Using Assembly Conveyors

Why should you consider implementing assembly conveyors in your production line? Here are some compelling reasons:

1. **Increased Efficiency**: Assembly conveyors minimize the time workers spend moving products manually. With items seamlessly transported along the line, employees can focus on assembly tasks, drastically improving overall efficiency.

2. **Reduced Labor Costs**: By automating material handling, companies can reduce the number of employees needed for manual transport. This not only lowers labor costs but also allows you to allocate resources to more skilled tasks.

3. **Enhanced Safety**: Manual handling of heavy or awkward items poses a risk of injury. Assembly conveyors take on the burden, reducing the risk of workplace accidents and ensuring a safer environment.

4. **Improved Product Quality**: With a consistent flow of materials, the likelihood of errors decreases. Assembly conveyors help maintain quality standards by providing precise control over the assembly process.

Choosing the Right Assembly Conveyor

Selecting the perfect assembly conveyor for your production line can feel overwhelming given the myriad of options available. Here are some factors to consider:

1. **Type of Products**: Consider the size, weight, and shape of the items you’ll be transporting. Certain conveyors excel at handling specific types of products.

2. **Layout of Your Facility**: The design of your workspace can dictate the type of conveyor system that will work best. Evaluate your production flow and spatial constraints before making a decision.

3. **Speed and Capacity**: Determine the throughput needed for your operation. Some conveyors can transport goods faster and handle larger volumes than others.

4. **Budget**: Finally, consider your financial constraints. While investing in a quality assembly conveyor can lead to long-term savings, it’s essential to find a solution that fits your budget.

Maintenance and Care for Assembly Conveyors

Like any machine, assembly conveyors require regular maintenance to ensure optimal performance. Here are some tips to keep your conveyor in top shape:

1. **Regular Inspections**: Schedule routine checks to identify any wear and tear. Catching issues early can save you from costly repairs down the line.

2. **Keep It Clean**: Dust and debris can hinder the operation of your conveyor. Regular cleaning not only maintains efficiency but also extends the life of the equipment.

3. **Lubrication**: Ensure that moving parts are well-lubricated to prevent friction and overheating.

4. **Train Your Staff**: Educate your team on proper usage and maintenance practices. An informed workforce can significantly reduce the likelihood of mishaps.

Conclusion

Assembly conveyors are the unsung heroes of the manufacturing world, quietly ensuring that products move efficiently through the assembly line. By understanding their function, benefits, and maintenance needs, you can make informed decisions that enhance your production capabilities. With the right conveyor system, you can elevate your operations to new heights, boost productivity, and ultimately drive your business forward.

FAQs

1. What types of assembly conveyors are available?

There are several types, including belt conveyors, roller conveyors, chain conveyors, and modular conveyors, each designed for specific applications and product types.

2. How can I determine the right conveyor for my needs?

Assess your product dimensions, weight, and production layout. Additionally, consider the speed and capacity requirements to choose the most suitable conveyor system.

3. How often should I maintain my assembly conveyor?

Regular inspections should be conducted monthly, while cleaning and lubrication can be done more frequently based on usage and environmental conditions.